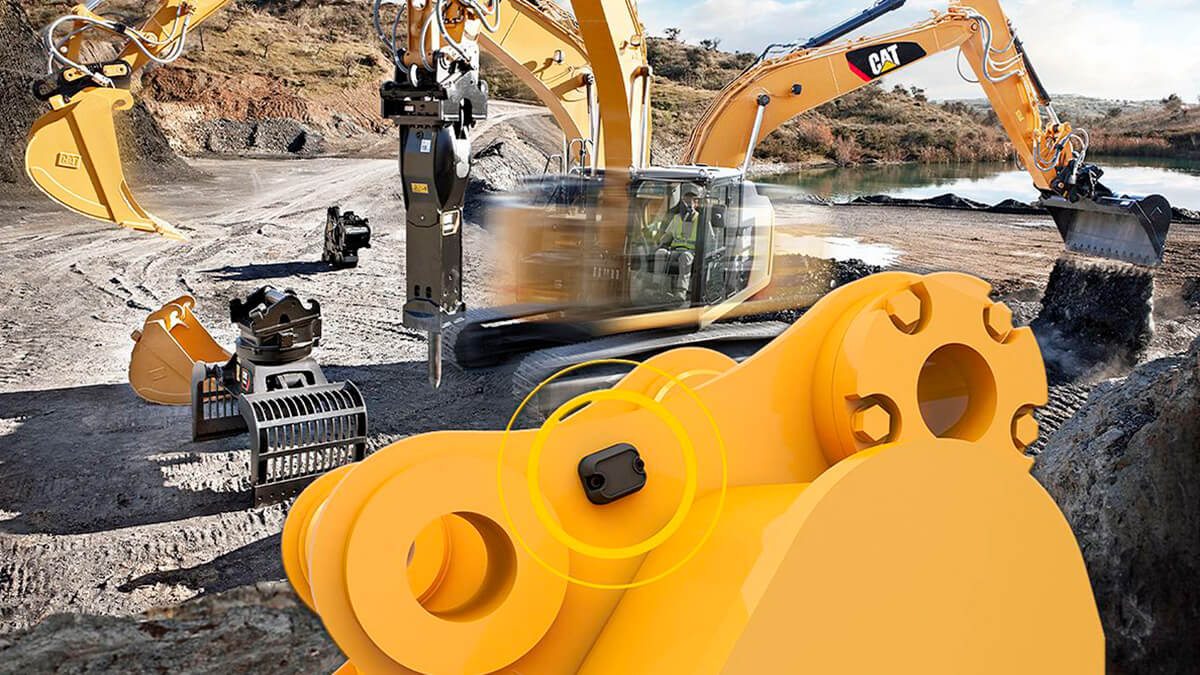

Work tools tracking & work tool recognition CAT PL161 (A). AUTO STOP function on the CAT New Generation Excavators (NGH) during CAT hammers operation (B).

(A) All the Work Tools, such as: multiprocessors, crushers, shears etc. are configurated with the CAT PL161 as standard.

The CAT PL161 allows:

How does the CAT PL161 operate?

The CAT PL161 sends a signal to Bluetooth receiver in the machine, then the machine sends all the data (about the machine and the Work Tool) to a special monitoring system CAT VisionLink via sputnik or mobile network.

The second option, used to detect the current machine’s location, works through a mobile app (which should be installed on the phone) CAT App. The mobile App receives the GPS coordinates of the smartphone, and then CAT App sends the data about the current location to a special monitoring system CAT VisionLink. When this option is used, the smartphone should be within 30 meters radius from the Work Tool.

In both cases, the client will have information about the location of his attachment.

How does the CAT PL161 detect the number of operating hours of the Work Tool?

Each CAT PL161 has a built-in monitor sensor that detects movement of the Work Tool (due to vibration). Depending on what type of movement occurs with the attachment, an “intelligent filter”, which works based on the mathematical algorithm, determines the operating hours of the attachment. Constantly received data is recorded under each Work Tool ID.

(B) The AUTO STOP function of the CAT NGH excavators has been embedded and designed to work efficiently and correctly with the CAT hammers. This function helps to avoid overheating and deformation, which ensures the durability of the machine and the hammer itself.

What is the work principle of this function?

When working with a hammer, operators often try to break the material with constant and monotonous blows by a hammer in one point, which is wrong. The hammer should break the rock within the first 15 seconds. If that doesn’t happen, then the operator should replace the position of the tool.

This function warns and prevents incorrect operation by automatically stopping. After 15 seconds of hammering, an alert appears on the screen that it is necessary to change the position of the tool, and after 30 seconds, the hammer is automatically turned off. Hammer operation can be resumed after the operator changes the tool position and restarts the process.

All the notifications will be displayed on the sensor screen, which is installed in the CAT NGH excavators.

The CAT PL161 and the AUTO STOP function help our customers when working on the CAT NGH excavators.

Caterpillar has a line of Work Tools and machines to help our customers get the most out of their demolition work. The ability to have both, the excavator and Work Tool from CAT, makes it easier for our customers to install and maintain all the equipment they have.